Welcome to class number 11. We're going to be talking about concrete. One of my favorite materials to work with. Concrete is remarkable. It's flexible. You can pour it into a form of any shape, any size. It will conform to that shape and produce a very interesting looking end result. You really should take advantage of that property of concrete and look for creative, attractive shapes, instead of the typical square boxes that we see too much of. It's easy and inexpensive to give the concrete an appearance that we will all admire for the long life of the structure.

You can also take advantage of the natural patterns of the formwork and the ties and integrate them into your design, so that they're not just the random pattern, but they serve to improve the look of the end product. You can create grooves and all kinds of fenestrations to improve the finished appearance. My own personal preference is to stay with the natural look of the concrete and not try to introduce some kind of artificial pattern, use a form liner, which imparts some artificial appearance to the surface. For my part, the concrete is very handsome as it's cast, and I'd rather have real concrete than fake looking anything. Bottom line, give the appearance a great deal of thought. People will be looking at these structures for a very long time.

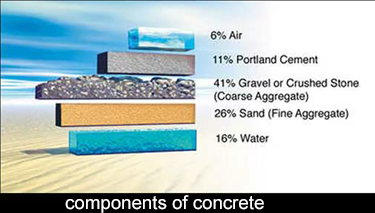

What is concrete? I'm using this graphic because it has a very interesting look and also because it lists as the first ingredient, air. I think most people, if you ask them to list the ingredients and concrete, they would not include air. But it turns out air is very important. It leads to a much more durable product. In fact, an essential ingredient. It usually occurs naturally when you mix concrete, but you can also use an additive which will ensure that you get the amount of entrained air that you're looking for.

What is concrete? I'm using this graphic because it has a very interesting look and also because it lists as the first ingredient, air. I think most people, if you ask them to list the ingredients and concrete, they would not include air. But it turns out air is very important. It leads to a much more durable product. In fact, an essential ingredient. It usually occurs naturally when you mix concrete, but you can also use an additive which will ensure that you get the amount of entrained air that you're looking for.

While I enjoy the look of this graphic, I would be very cautious about the percentages of the various ingredients. I'm not sure I agree with that at all. They show 16 percent water. I think that would be a very weak mix. I believe a good mix requires much less water than that. Nevertheless, this graphic comes from the Portland Cement Association, a very well-respected to body of people. It is a nice representation of what is contained inside the concrete.

While I enjoy the look of this graphic, I would be very cautious about the percentages of the various ingredients. I'm not sure I agree with that at all. They show 16 percent water. I think that would be a very weak mix. I believe a good mix requires much less water than that. Nevertheless, this graphic comes from the Portland Cement Association, a very well-respected to body of people. It is a nice representation of what is contained inside the concrete.

: What I learned as a tool early on was a ratio of one to two to three and a half. It has served me well, whenever I had to mix a little concrete in the backyard for a fence post. It would be one shovel full of cement two shovelfuls of a fine aggregate, usually sand and three shovelfuls of a coarse aggregate -some kind of gravel or broken stone.

That produces a very good result and if you want to have a little clue in the back of your head of the proportions, 1 to 2 to 3 and a half, I think, would serve you well. After you combine the dry ingredients, you add only enough water to make the mix workable.

The addition of more water will make it easier to work with. And that's why people add more water, but it radically reduces the strength of the concrete. You need to exercise self-control and limit the amount of water that you add. Only sufficient to make the mix workable. In this day and age, if you need to a little concrete for the backyard, you'd buy a bag already mixed in Home Depot. But when you get home again, add only enough water to make it workable.

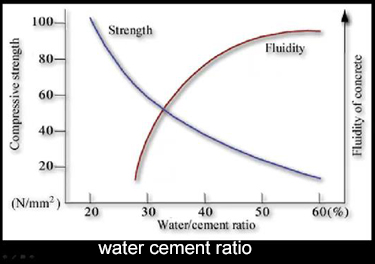

Here is a chart that shows the effect of adding water to concrete. The blue curve begins with the highest strength and falls off dramatically as you add water. Adding water is something that you must control. If you add too much water, you've sacrificed the strength of the concrete. There's no undoing that. Once the water is in there, you're going to use that concrete and get poorer results.

Here is a chart that shows the effect of adding water to concrete. The blue curve begins with the highest strength and falls off dramatically as you add water. Adding water is something that you must control. If you add too much water, you've sacrificed the strength of the concrete. There's no undoing that. Once the water is in there, you're going to use that concrete and get poorer results.

Now, of course, if you overdo it, you really should reject that concrete truck and send it away, but in the real world this rarely happens. You need to begin by carefully controlling the amount of water that goes in. You really don't have to carry around in your head the ratios 1 to 2 to 3 and a half and how much water. This is all figured out in advance in a laboratory. For each project, you need a lab to sample the actual materials that will be used on your project and produce a design mix, including recommendations for how much water needs to be used.