We have a video showing the jump made by these internally mounted tower cranes. The video is made by DCM Erectors. The cranes shown here are the same as the cranes on our site. This is actually the Times Tower in Manhattan.

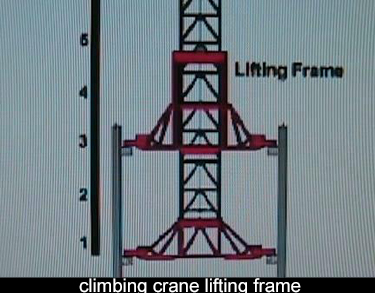

Here's the schematic section. What I've been calling a frame, they call a basket. We'll switch to that terminology, although basket doesn't really please me - and this is the lifting frame

Here's the schematic section. What I've been calling a frame, they call a basket. We'll switch to that terminology, although basket doesn't really please me - and this is the lifting frame

They're beginning at 8:00 am, and we'll see exactly how long this takes. They start by stripping away any of the protective fencing, safety nets - anything that inhibits the movement of the crane. They make sure that it's clear. That's the engine that drives a pump that provides the hydraulic power. The foreman is operating these levers. I like that little notice on the steel to move the crane up. Move the cylinder. Move the lever this way. Keep it simple. There are a pair of these cylinders.

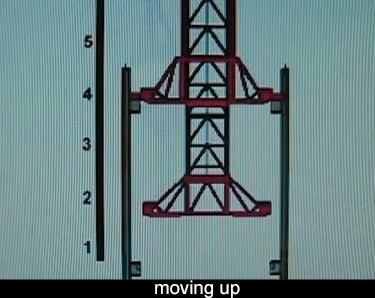

When the lugs are retracted, you can now lift the upper basket. The cylinders are actually lifting the upper basket one story. Then they re-support it, extend the lifting frame again, and then raise the upper basket again.

Now, it's in position to be attached to the structural frame. Those are the outriggers being moved out. They rest on brackets on the structural frame.

Now, the tower is being raised together with the crane. The jump has been completed in two hours. By noontime, they can actually raise both of these cranes, which is quite remarkable. Let me just read this to you. It may not be clear.

They are pointing out that the jumping time is much faster. Two hours is really quite remarkable. Just a short tower is required, instead of a tower that goes from the crane all the way down to the street. It can be attached to the structural frame without any modification. It requires no redesign of the frame in any way. There's minimal interference with the work of the trades.

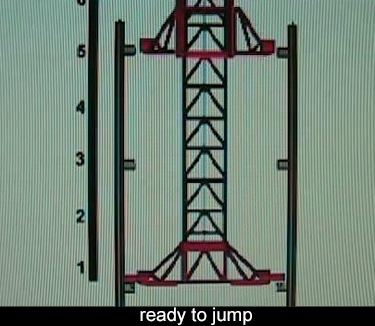

Here again, I'm just summarizing what's taking place. It goes by a little quickly in the video, and it's not exactly perfectly indicated. There are the three elements required: the lower basket, the intermediate basket and the lifting frame. They're ready to go, but really, before you can make a jump, you need the next two stories of steel to be in place. This drawing is not quite there.

Now you see the motion of the lifting frame? It goes up one story. It brings the basket up one story. The basket needs to be attached and the process is repeated. Now the outriggers are extended and, when they are in place, you can now lift the entire assembly. That's how the video stops. It's not quite complete. There's something a little unsatisfying about the video.

Now you see the motion of the lifting frame? It goes up one story. It brings the basket up one story. The basket needs to be attached and the process is repeated. Now the outriggers are extended and, when they are in place, you can now lift the entire assembly. That's how the video stops. It's not quite complete. There's something a little unsatisfying about the video.

It seems that the hydraulic cylinders can only Advance one story at a time. This final move, which raises the crane and the tower, looks like, perhaps it has to take place in two stages. They may have just simplified that. I don't know if it can be done all at once.