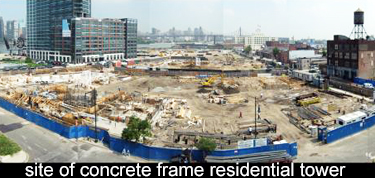

Welcome to class 17. In the previous class, we looked at high-rise construction, utilizing a steel frame and creating a commercial office tower. Now we're going to look at a different technique. This is a concrete frame building and the finished product will be a residential Tower. This is the site at the very earliest stage of construction on the left side. You can see the first tower that was constructed in this redevelopment area. This is in Queens, New York, beautiful site, right on the East River. That first tower was a success and now several additional buildings will be constructed. We be examining the building in the foreground. The piles had already been driven before I began filming this construction. I'm going to switch to a different site, which uses a similar pile foundation, so that you can get a look at what that process is like.

Welcome to class 17. In the previous class, we looked at high-rise construction, utilizing a steel frame and creating a commercial office tower. Now we're going to look at a different technique. This is a concrete frame building and the finished product will be a residential Tower. This is the site at the very earliest stage of construction on the left side. You can see the first tower that was constructed in this redevelopment area. This is in Queens, New York, beautiful site, right on the East River. That first tower was a success and now several additional buildings will be constructed. We be examining the building in the foreground. The piles had already been driven before I began filming this construction. I'm going to switch to a different site, which uses a similar pile foundation, so that you can get a look at what that process is like.

I wanted you to have a look at pile-driving equipment and just watch the behavior of this pile. It's quite unusual. It passes through a very thick layer of very soft material. You will call that a push. The hammer is not even working. The weight of the hammer itself is pushing the file through this soft material. A layer of soft material like that can be a real problem in terms of how will these roadways begin to settle over time. Once you add load to this very compressible layer, you can expect some long-term settlement.

Here, the pile is being driven, not to refusal. Refusal would mean driving it to rock where it simply won't go any further. This pile seems to be advancing. Some pre-determination has been made as to when it reaches satisfactory resistance. The inspector who is tracking the progress is looking for this predetermined amount. It might be six or eight or ten blows to advance the pile and inch. This has been worked out in advance and he's just there to verify that the pile is reaching this predetermined amount.

Here, the pile is being driven, not to refusal. Refusal would mean driving it to rock where it simply won't go any further. This pile seems to be advancing. Some pre-determination has been made as to when it reaches satisfactory resistance. The inspector who is tracking the progress is looking for this predetermined amount. It might be six or eight or ten blows to advance the pile and inch. This has been worked out in advance and he's just there to verify that the pile is reaching this predetermined amount.

You can see it's getting very, very close to the ground and he is counting these last few blows in another minute. The rig really will not be able to advance it any further. We're all waiting to see if this is a good pile or not inspect the signals it's okay. You can only wonder if he was under the pressure of calling it good before the pile driving would have to stop in any event. Then you would have to splice another section onto the pile and continue driving.

If it falls short, you may have to increase the number of blows per inch and try again until you develop a pile, which has the capacity that you want. In this case, the platform of weight looks like it's a series of pig iron blocks, but it can be concrete blocks. It can be even a precast concrete barriers, whatever material you have available.

Under certain circumstances, you can drive a pile on either side of the test pile and actually Jack against the two adjoining piles. Of course, the adjoining piles have to have tremendous resistance against uplift, because you don't want to pull them out of the ground before you've reached the capacity for your test. This is how you test the capacity of a driven pile right on your site and determine that you're using or verify that you're using the correct driving criteria.

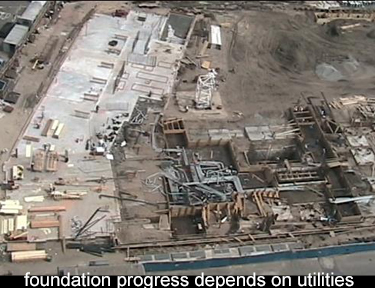

It's impossible to overemphasize the importance of utilities. This needs to be addressed at the very, very earliest point in the planning for the project. The approval by all the agencies takes forever. No matter how much time you allow, it's usually not enough time. This has to be your highest priority. Even here you can see the foundation slab has already been constructed up to this area where the utilities have to be installed. It looks like this is already impacting the progress of the foundation. I'm going to continue with a video of some of the early construction activities.

It's impossible to overemphasize the importance of utilities. This needs to be addressed at the very, very earliest point in the planning for the project. The approval by all the agencies takes forever. No matter how much time you allow, it's usually not enough time. This has to be your highest priority. Even here you can see the foundation slab has already been constructed up to this area where the utilities have to be installed. It looks like this is already impacting the progress of the foundation. I'm going to continue with a video of some of the early construction activities.

I think it's pretty clear that the foundation is gone about as far as it can, and it cannot really proceed effectively until the utility work is completed.

I think it's pretty clear that the foundation is gone about as far as it can, and it cannot really proceed effectively until the utility work is completed.

The utility work has been completed, foundation slab poured, and now they are forming for the first floor. This is not the typical arrangement of forming. This is atypical, because this is the building lobby. The ceiling height is much higher. Pipe scaffolding is being used here with aluminum joists, and the lobby looks quite different. A lot of hand labor goes into doing the lobby. This trade are called lathers in New York City. The rebar is handled by lathers. Elsewhere, it's typically Ironworkers. These lathers are engaged in making cages for the column construction.

The utility work has been completed, foundation slab poured, and now they are forming for the first floor. This is not the typical arrangement of forming. This is atypical, because this is the building lobby. The ceiling height is much higher. Pipe scaffolding is being used here with aluminum joists, and the lobby looks quite different. A lot of hand labor goes into doing the lobby. This trade are called lathers in New York City. The rebar is handled by lathers. Elsewhere, it's typically Ironworkers. These lathers are engaged in making cages for the column construction.

Another thing unique to New York City is that the lathers bend the rebar on site. Every place else it's bent by the fabricator. It comes out already pre-bent. You can imagine there's a tremendous amount of extra effort to just carry the bars over to this bending machine, bend them. It really, two people, and they're going back into another pile now. There's a lot of added labor at the site. This was annoying to me. The lather makes the first band, but he can't make the second band until his buddy comes over and supports the other end. Obviously, if you made a little saw horse to the correct height they could carry that.

I excluded the troublesome page (https://csites.com/classes.htm) but need to wait untill tomorrow to recrawl.