Here's a video I made showing the installation of Steel sheet piling. Here, they've lifted two sheets. That's actually a pair of sheets. And of course, if you can progress two sheets at the same time, you can double the rate of production. It's challenging to align one sheet with the next. It actually takes three people to do this. They've managed to join the sheets and now they're lowering the new sheets.

Even though the sheets are engaged, they're not going down very easily and I think that's because the new sheets are plumb. They are hanging by gravity, so they're quite vertical. But the sheets that are already driven are somewhat out of plumb. And as a result, there's a real struggle for trying to get these new sheets to go down.

Even though the sheets are engaged, they're not going down very easily and I think that's because the new sheets are plumb. They are hanging by gravity, so they're quite vertical. But the sheets that are already driven are somewhat out of plumb. And as a result, there's a real struggle for trying to get these new sheets to go down.

As I pointed out earlier, it's better not to fully drive the sheets, to only partially drive them, and then join more sheets because it's a little easier to try to adjust them as a group. At this point, there really is no adjustment. The earlier sheets are fully driven and you're stuck with that result. If it's a little out of alignment or out of plumb, there's not much you can do about it, but simply join the next sheet and hope that the problem doesn't keep growing.

Now the new sheets have been joined. The foreman is trying to get them plumb. He must sense that they're not quite vertical, so he's advancing the rig a little to try to get them vertical. Now he's lowering the hammer on top of the sheets and getting ready to drive the new sheets.

When he's finally ready, look for him to tap his hard hat. That's a universal signal that it's okay to start driving a pile.

Now he started driving the sheeting. I'm not sure driving is the correct expression, because he's using a vibratory hammer. This is not an impact hammer. He's vibrating it into the ground. It's very effective. You can see how quickly the sheets are descending. He's advancing them two at a time, and still they seem to represent little or no resistance, he's making excellent headway here.

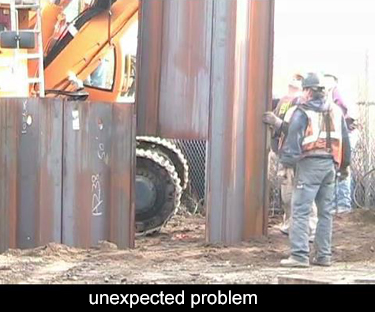

I always hang around and shoot some additional footage, or produce some additional video. You always want some extras in case there's something in the first take that you really weren't happy about. Now they've engaged the next two sheets, and I'm glad I stayed around because it was some real surprises.

The sheets have separated. No one was standing close enough to get injured, but this certainly surprised them. Once again, I think it's because the new sheets are not riding freely in the driven sheets. They get hung up there, the sheet on the right has no restraints, so it simply came apart. As I recall from my own experience, the foreman tack welds the sheets together so that they cannot separate. Now you can see why that's really necessary.

The sheets have separated. No one was standing close enough to get injured, but this certainly surprised them. Once again, I think it's because the new sheets are not riding freely in the driven sheets. They get hung up there, the sheet on the right has no restraints, so it simply came apart. As I recall from my own experience, the foreman tack welds the sheets together so that they cannot separate. Now you can see why that's really necessary.

He's now driving this pair of sheets, but you can see that they are really way out of plumb. There's not much he can do about that at this point, because he is simply a victim of the sheets that are already in the ground.

Try as he may, he simply cannot advance these sheets, and he eventually stops. I picked up the camera and left. I did not want to hang around and just record his struggle or embarrass anybody, but the lesson to be learned here is that you really cannot cut corners. There's no substitute for good practice and the idea of driving the sheets in a progressive way is very advantageous.