Here is an illustration of a steel sheet piling installation. The workers here are engaged in installing a whaler. The whaler here is made up of double channels, back-to-back with a space in between them. The space is to accommodate the installation of tiebacks. The method of supporting the steel sheet piling in this instance, will be through the use of tiebacks.

While we're here, I wanted to point out the backhoe, which is sitting on top of this bank and reaching inside to excavate material and place the material in the waiting dump truck. You can see how close it is to the excavation. The backhoe is mounted on caterpillar tracks and that distributes the load and spreads the load. And I'm sure what he's doing is perfectly safe, but I wanted to point out how, invariably, equipment comes very close to excavations.

In this slide, the tiebacks are being installed. That's a drill that's drilling a hole through the space in the whaler, and they will drill a hole into the earth in this case and sometimes into the rock. These I recall were earth anchors. A calculation has to be made as to how deep to drill the hole. Then high-strength steel rods, or bundles of high-strength cable are inserted into the hole and grouted in place. When the grout is set. A load is applied to the anchor to prove it and the load is then locked into the whaler. That's the system that ties back the steel sheet piling.

In this slide, the tiebacks are being installed. That's a drill that's drilling a hole through the space in the whaler, and they will drill a hole into the earth in this case and sometimes into the rock. These I recall were earth anchors. A calculation has to be made as to how deep to drill the hole. Then high-strength steel rods, or bundles of high-strength cable are inserted into the hole and grouted in place. When the grout is set. A load is applied to the anchor to prove it and the load is then locked into the whaler. That's the system that ties back the steel sheet piling.

This is an alternate system for bracing the steel sheet piling. In this case, it is done with pipe struts.

The pipe struts bear against the whaler, which is attached to the steel sheet piling. The pipe strut is very efficient compression member, capable of carrying very high loads. As the width of the excavation increases, the dead load of the pipe strut becomes a very important factor and pipe struts can grow to be 36 or even 48 inches in diameter. I've also had occasion where I've added cover plates, top and bottom to the pipe strut in order to get it to span the distance that we needed.

In some cases, it is even necessary to introduce intermediate supports, because the distance is simply getting too great to span. The drawback of the intermediate support is that it will no doubt interfere with whatever it is you're trying to construct inside the excavation.

These are all factors that the engineer must take into account. First of all deciding should he use tiebacks, which would create an open obstruction free excavation? Or should or she use a pipe struts as illustrated here? And what's the most efficient spacing of the pipe struts? When do you need to introduce intermediate supports in order order to use lighter sections?

This is a building site. And I would like to mention that there are two distinct disciplines within the civil engineering community. One is heavy construction, and the previous slides have demonstrated heavy construction, which is typically Public Works structures: Highways Bridges, tunnels. Railroad facilities.

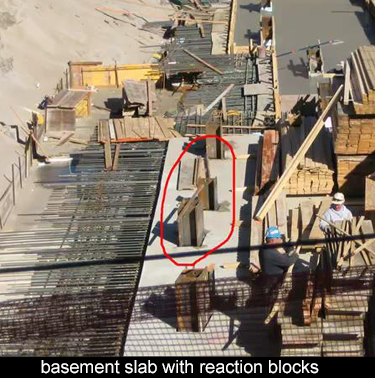

Illustrated here in the photo is building construction, a different discipline. Both of them require civil engineering solutions to very complex support of excavation challenges. Here, in the case of this building and many buildings, a different approach is taken. They need to excavate down to get to the foundation slab and that's quite deep in the hole.

Illustrated here in the photo is building construction, a different discipline. Both of them require civil engineering solutions to very complex support of excavation challenges. Here, in the case of this building and many buildings, a different approach is taken. They need to excavate down to get to the foundation slab and that's quite deep in the hole.

They begin by excavating someplace in the middle of the hole and that leaves a good deal of undisturbed soil, which is still capable of supporting the steel sheet piling. I would like to point out that here again, steel sheet piling is the method used around the perimeter of the excavation, because of the presence of a very high water table.

You could not brace from one side of the excavation to the other. The braces would be impractically long. The presence of a lot of intermediate supports would make the further future construction very, very difficult to achieve.