Here is a detail from the foundation slab. I want to point out the short stubby columns which have been cast into the slab, and they will be used in order to brace the steel sheet piling.

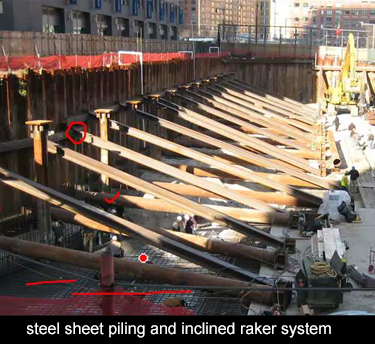

This is the next stage of the operation. To begin with, horizontal whalers have been installed up against the sheet piling. Then incline braces are installed and they come to bear on these short stub columns, which have been cast into the foundation slab. An inclined brace like that is called a "raker" and this method is called the "raker method." When these inclined rakers have been installed, the backhoe can reach between them and excavate the area previously left undisturbed up against the sheeting.

This is the next stage of the operation. To begin with, horizontal whalers have been installed up against the sheet piling. Then incline braces are installed and they come to bear on these short stub columns, which have been cast into the foundation slab. An inclined brace like that is called a "raker" and this method is called the "raker method." When these inclined rakers have been installed, the backhoe can reach between them and excavate the area previously left undisturbed up against the sheeting.

The excavation is now taking place and it's bringing the grade down to a point roughly equal to the top of the foundation slab. When the excavation is brought to the top of the previously built slab, then you're able to install these horizontal braces. These braces also react against the short columns cast into that slab.

These horizontal members are struts or braces, and it's interesting to point out that they are pipe sections. As I mentioned before, the loads here have increased the deeper you go in the excavation, the greater the loads. At this point it was felt that a pipe section would be better suited. Where as the inclined rakers were rolled sections.

One advantage of the rolled section is that the end connections here are much simpler than they would be with a pipe section. After this horizontal brace has been installed, you can now further excavate to the subgrade. You're now able to install the rebar and pour the foundation slab out to the steel sheeting.

You can see some evidence here of white color under the floor slab. That's a waterproofing membrane which has been placed. It's absolutely essential to waterproof any deep excavation, especially this one, which is below the water table.

This has been done by first placing a membrane and then constructing the floor slab or foundation slab on top of the membrane. It's beyond the scope of this lecture to go into the details of waterproofing concrete structures. A very complex and very important subject, but needs to be dealt with elsewhere.

The foundation slab has been poured right up to the steel sheeting, and the steel sheeting can react up against the foundation, and that lower pipe strut can be removed. It has already been removed in this area, but here in an area where the concrete is not in place you can see all of the elements.

You begin here with an inclined brace, which I call a raker. You can then excavate further down until you're able to install this horizontal brace, which I would call a strut. Then you can excavate below that to get down to the subgrade and you can then construct the next pour of the foundation slab. When that foundation slab is constructed. You can then remove the pipe strut. It's important to remove it, because it will be in the way of the foundation wall, which would be the next element to be constructed.

In this photo. the foundation wall is now being formed. They're putting up scaffolding and formwork for the exterior foundation wall for the building. As you can see, all of the incline braces remain in place, and they must be in place to carry the load on the steel sheeting. They will have to be in place until the foundation wall is complete, and is itself brached by the floor slabs. Then the inclined braces can be removed, and the loads can be transmitted to the foundation wall.

I'd also like to point out that here in the background the structural steel is already being erected. This is called fast-tracking. Instead of waiting for the entire foundation to be constructed, the structural steel can start at one end of the building and work productively, even while the foundation construction continues.