Here is the process for constructing a slurry wall. To begin you construct starter walls, and you can see them in this photo. There are two concrete walls. They don't have the scalloped shape as you would use for a secant pile wall. These are just straight walls to guide the bucket doing the excavation.

And that is the bucket. It's quite massive, because it depends on its size to go down perfectly, vertically and to keep following the same path to quite a depth. Slurry walls, in my experience, I've built them over a hundred feet deep, and I've been on projects where they've been constructed over 200 feet deep.

This was filmed in Boston, where there's clay. A very deep layer of clay. And you can see the material come out in one solid piece of very stiff clay. The red pipe in the background is pumping fresh slurry into the trench. The trench is being excavated at quite a rapid pace and the slurry must be constantly replaced to keep it at that level. You depend on a trench filled with slurry in order to keep the sides of the excavation open.

The crane being used is an ordinary crawler crane. There's nothing special about the crane. What is special and what is unique to slurry wall construction is this bucket, which is designed to remain perfectly vertical and also to open and close its jaws within the confines of the slurry wall.

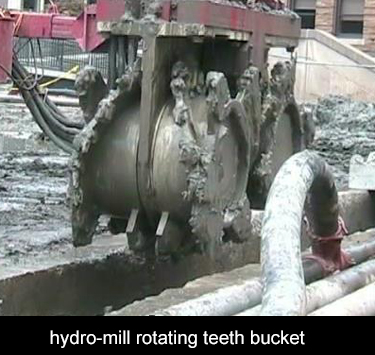

This is a different kind of device. It's a hydro mill. It is not a clamshell bucket, as we saw in the previous clip. This is a different way to excavate for slurry walls and fortunately, both techniques were being used at this site, so that I could capture both of them.

This is a different kind of device. It's a hydro mill. It is not a clamshell bucket, as we saw in the previous clip. This is a different way to excavate for slurry walls and fortunately, both techniques were being used at this site, so that I could capture both of them.

The laborer on the right is standing on a group of pipes and those pipes go around the perimeter of the project. They bring fresh supplies of slurry to the excavation and they also carry away the slurry that's being displaced as you fill the trench with concrete. Also interesting to point out the labor on the right is wearing a life preserver, which I think is an excellent idea, but the other people on the site are not wearing life preservers.

The constant hosing down of the equipment is more than just cosmetic. The equipment comes out of the trench coated with slurry. I believe, as the slurry dries, it would harden and begin to build up quite a film on the equipment. They constantly hose it down, so that you cannot develop that film.

I've actually sped it up the video here, because it was taking forever to raise bucket out of the hole. I don't know if that was an excess of caution, or if the operator was just stretching out the time, because this was getting very close to lunchtime.

You can see, just coming out of the trench, that's actually a pump. In this process, you grind the excavated material. You actually liquify it so that a pump can pump it out of the excavation. Now you can see the cutting heads. It's quite different than the clamshell bucket. These are rotary heads, which are outfitted with teeth and they can dig through very stiff material. They can actually dig into rock.They can also be used to remove the clay just the same way that you would remove it with the clamshell bucket.

This is a good overview. You can get a sense of the size of this equipment. If you compare it to the operator at the left of the screen.