The tiebacks you're looking at here are new. Also, the wall has been coated with a shotcrete or gunite as a protective coating. The surface of the wall was quite deteriorated. I don't know if that's the result of being in service for 40 years, or if it was the result of the 9/11 event, but it required some immediate attention. The entire wall has been coated with this shotcrete application.

A part of the wall is to be left open to the public as part of the memorial installation. Visitors will be able to walk down and look at the existing wall. Some other interesting features in this photo. This is a column for the Freedom Tower, but it's somewhat ceremonial, because the column was erected about the beginning of 2007 and there has been a lot of progress on the foundation for the Freedom Tower, but the superstructure has not yet started. A year and a half later, we are still waiting for a start date for the superstructure.

There was an area of the existing slurry wall that was not shotcreted over and you can see its condition post 9/11. There's a great deal of exposed rebar. The surface has been lost either over time, or as a result of the 9/11 event. I wanted to share with you what the condition was after site was re-excavated.

There was an area of the existing slurry wall that was not shotcreted over and you can see its condition post 9/11. There's a great deal of exposed rebar. The surface has been lost either over time, or as a result of the 9/11 event. I wanted to share with you what the condition was after site was re-excavated.

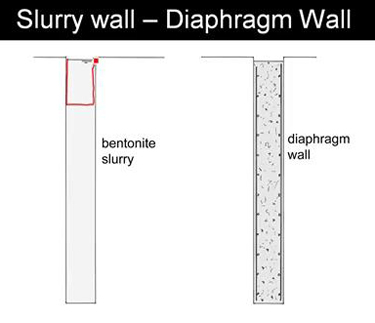

What is the slurry wall? And how do you build a slurry wall? I'm going to go back here to some definitions. First of all, the wall we are looking at in the photos and the walls we generally refer to when we use the expression slurry walls on not slurry walls at all. They are diaphragm walls that are structural reinforced concrete walls. It's constructed using a bentonite slurry process, but the term slurry wall is a kind of a slang abbreviation and it stuck and the whole world uses it and there's no reason why you should not be using it.

How do you build a slurry wall? You know that if you excavate a trench to any depth at all, the sides of the trench will begin to collapse and fall in. It was discovered that by introducing a bentonite slurry, the hydrostatic head of the slurry, was sufficient to keep the sides open. This was a remarkable discovery and permitted very deep excavations.

How do you build a slurry wall? You know that if you excavate a trench to any depth at all, the sides of the trench will begin to collapse and fall in. It was discovered that by introducing a bentonite slurry, the hydrostatic head of the slurry, was sufficient to keep the sides open. This was a remarkable discovery and permitted very deep excavations.

To begin with, what Is Bentonite? Bentonite is a naturally occurring clay. You mix it with water to form a slurry and you keep the trench filled with this slurry. I always imagined that Bentonite slurry must be some very thick, heavy, viscous material and that's what keeps the trench open. Well, that's not the case at all. It's actually not much different than water in its appearance.

The Bentonite has a quality of lining the surface and creating almost a membrane. The Bentonite coats the surface of the excavation as you go down and it seals the surface.You continuously fill this trench with the Bentonite slurry and it stays there. It does not get absorbed by the soil surrounding the trench. That hydrostatic head is sufficient together, with this mysterious lining coating quality of the Bentonite, that keeps the sides from collapsing.

You can go down very deep. I have gone down over 100 feet. I've been on a project where they went down over 200 feet. At the World Trade Center that slurry wall is, I believe, around 60 feet deep. You can also drill shafts, and keep the sides of the shafts from collapsing, or you can drill horizontally and keep that hole from collapsing all by introducing a bentonite slurry. So there are wide applications for Bentonite, because of its unusual properties.

After you've completed the excavation, you lower a cage of rebar into the trench. That in itself is quite a challenge, because you have assembled this rebar cage horizontally. You now have to pick it up, rotate it in the air and lower it. It's a very unstable, very flexible cage, and it takes a little bit of trial and error until you finally figure out exactly how to do this, turn it in midair and lower it vertically in place. After that, you fill the trench with concrete and the concrete displaces the slurry which you have to capture.

The end result is a very strong, reinforced concrete wall, which is called a diaphragm wall. So you begin with bentonite slurry. You end up with a diaphragm wall and that has been kind of abbreviated into the expression slurry wall.