Welcome to class 14, where we will examine, removing and replacing a bridge and accomplishing that in a remarkable six months.

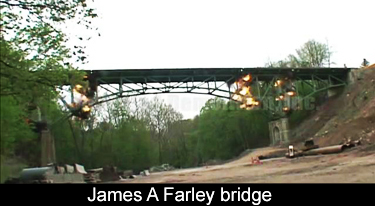

This is a view of the James A Farley bridge in Stony Point, New York. The bridge was deemed deficient and was scheduled to be removed and replaced, and we are going to examine that entire process. Farley was a prominent politician during the Roosevelt/Truman era. He was extremely popular because the main post office in Manhattan is named after him and this bridge is also named after him, because he was born in Stony Point NY.

This is a view of the James A Farley bridge in Stony Point, New York. The bridge was deemed deficient and was scheduled to be removed and replaced, and we are going to examine that entire process. Farley was a prominent politician during the Roosevelt/Truman era. He was extremely popular because the main post office in Manhattan is named after him and this bridge is also named after him, because he was born in Stony Point NY.

Here is a detailed view. You can see some preliminary cutting of the existing bridge has already been done. The roadways have been cut here. You can see the daylight shining through, and the charges are in place on the primary cause of the bridge, and also on the secondary diagonal members. The bridge is now ready for this controlled demolition.

The charges are timed. There is a slight delay between the charges. The bridge was initially cut at this point and that would allow this section to fall free. The next cut is made at this location, and this section of the bridge can now rotate into this empty space. The result is really remarkable. Here, you can see the concrete roadway has completely fallen away. I don't know if they were expecting that. It certainly is an additional benefit of this method. The sections of the bridge are just piled up here and can easily be dismantled and removed.

The charges are timed. There is a slight delay between the charges. The bridge was initially cut at this point and that would allow this section to fall free. The next cut is made at this location, and this section of the bridge can now rotate into this empty space. The result is really remarkable. Here, you can see the concrete roadway has completely fallen away. I don't know if they were expecting that. It certainly is an additional benefit of this method. The sections of the bridge are just piled up here and can easily be dismantled and removed.

The entire process from beginning to end took about two weeks. You can compare that to the previous bridge, which had similar dimensions where the superstructure was removed in about eight weeks.

The community had to choose between several options. The bridge could have been replaced in sections, which would have taken several years and certainly impacted the community and the flow of traffic throughout that duration. Instead, they accepted a proposal to demolish the bridge. That's really quite a remarkable undertaking, but they were assured that the bridge could be removed and replaced and reopen to traffic in just six months.

The way that was accomplished was by adopting a method which is somewhat unusual, Instead of a single contract managed over the duration by a single general contractor, they created three separate standalone contracts. The first contract was to furnish the structural steel. If you're familiar with these projects, you know that the shop drawing approval alone could probably take six months and then the steel has to be ordered from the mill and then fabricated. Certainly, that could be another six months. That needed to be handled in a separate contract and that's what was done here.

The second contract was for removing and replacing the existing superstructure. There the community was promised that that could be turned around in six months, and it was. Six months is still very ambitious, even though the steel has been fabricated in advance and is available to you immediately. The contract also provided an incentive for timely completion, as well as a penalty for failure to reopen the bridge on schedule.

There will also be a third follow-on contract, which will reconstruct the approach roadways to the new bridge. The existing bridge piers were demolished. They were not reused, and two new piers were constructed. Here, you can see the foundation for the new pier, which are drilled in piles.

We're going to review all of the elements of the construction that went into the building of the new bridge. This is the new pier that's under construction. What's interesting here is that the vertical steel for the pier is not coated rebar, and it's not clear to me under what circumstances coated rebar is used - and here, plain rebar is being used, In the previous bridge, the abutment walls always used coated rebar, and I expected to find it here in the bridge piers as well, but as you can, plain rebar is being used.

We're going to review all of the elements of the construction that went into the building of the new bridge. This is the new pier that's under construction. What's interesting here is that the vertical steel for the pier is not coated rebar, and it's not clear to me under what circumstances coated rebar is used - and here, plain rebar is being used, In the previous bridge, the abutment walls always used coated rebar, and I expected to find it here in the bridge piers as well, but as you can, plain rebar is being used.

continue >