I cannot overemphasize the need to carefully think through the appearance of the new structure for these piers, this corrugated shape was installed in order to give the face of the peir some interest, some texture, and to avoid that deadening look of just plain square concrete shapes. You'll be able to see and judge for yourself if this was an effective device. Certainly a lot of time and consideration should go into the final appearance of this bridge. This particular bridge, the space below the bridge was a public park. There was actually a great deal of activity and traffic below the bridge. The piers would get a lot of attention and under any circumstances, a lot of thought has to go into their appearance.

This view shows the erection of the formwork for the pier. The piers are tall. The loads on the forms are significant, and you can see that this is a more robust set of forms than we saw in the construction of the overpass. The overpass they were much smaller units that you could handle by hand. These are much heavier panels, and you can see the size of the crane here that's required to handle them.

Here we can see the column has been completed. The workers are attaching some brackets to the column. The brackets will support the form work for the pier cap. This assembly is the form work, at least for the soffit. If you don't know that term soffit, I mean, the underside of the pier cap. This assembly is structural. It's many panels are joined together to form a very strong and stiff beam. It will also form the underside of that hammerhead.

The formwork here is made of standard units, the same panels that are used to construct the pier -or to construct a wall. They're joined together here to form a beam. The panels are also used to create a work area, complete with a handrail for the remaining formwork, which will have to be installed. This is a very smart procedure. All of these members are ready-made members, very available and inexpensive to rent, and they're all assembled down on the ground. There's a minimum amount of assembly required up in the air. Of course, that makes this approach very safe and very cost-effective. However, it is a very heavy fabricated piece, and it requires a very big crane to lift it. Nevertheless, I think this is a much smarter operation than trying to build it out of small pieces.

The formwork here is made of standard units, the same panels that are used to construct the pier -or to construct a wall. They're joined together here to form a beam. The panels are also used to create a work area, complete with a handrail for the remaining formwork, which will have to be installed. This is a very smart procedure. All of these members are ready-made members, very available and inexpensive to rent, and they're all assembled down on the ground. There's a minimum amount of assembly required up in the air. Of course, that makes this approach very safe and very cost-effective. However, it is a very heavy fabricated piece, and it requires a very big crane to lift it. Nevertheless, I think this is a much smarter operation than trying to build it out of small pieces.

The industry has really adopted these ready-made panels. You can see it simplifies all of the process. But again, it limits, the appearance of the finished concrete. The assembly is being lowered very carefully on to the brackets. Brackets must be very high capacity, and they must be capable of withstanding a very significant load. These brackets have a screw adjustment, which is very smart, because that allows you to set the bracket at precisely the correct elevation. It also facilitates removing this form work, After the concrete is placed, the load has really been locked into the brackets. It would be very hard to remove these forms. You take advantage of that screw adjustment to unload the bracket.

The industry has really adopted these ready-made panels. You can see it simplifies all of the process. But again, it limits, the appearance of the finished concrete. The assembly is being lowered very carefully on to the brackets. Brackets must be very high capacity, and they must be capable of withstanding a very significant load. These brackets have a screw adjustment, which is very smart, because that allows you to set the bracket at precisely the correct elevation. It also facilitates removing this form work, After the concrete is placed, the load has really been locked into the brackets. It would be very hard to remove these forms. You take advantage of that screw adjustment to unload the bracket.

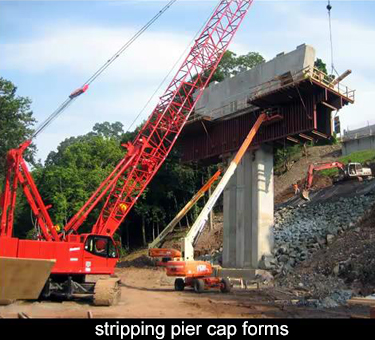

Here, the formwork for that pier cap is being removed. You can get a look at the overall pier. You can see the texture, that corrugated texture, in the face of the pier certainly broke up the surface, added some interest. And, up in the pier cap, they've tapered the ends. All of this is helpful. Could more have been done? Could they have gone a little further? I'll leave that to you, but it is at least encouraging to see that a lot of thought has gone into the appearance of these piers.

Here, the formwork for that pier cap is being removed. You can get a look at the overall pier. You can see the texture, that corrugated texture, in the face of the pier certainly broke up the surface, added some interest. And, up in the pier cap, they've tapered the ends. All of this is helpful. Could more have been done? Could they have gone a little further? I'll leave that to you, but it is at least encouraging to see that a lot of thought has gone into the appearance of these piers.