Now, we're going to discuss underpinning pits, a totally different concept, more suited to a supporting a continuous wall or a continuous foundation. This is a very old method and it is just passed along from generation to generation, completely unchanged. You still do it exactly the same way, because it is basically done by hand and nothing about it has changed or improved over the years.

When you have a continuous foundation, you dig an approach pit alongside the foundation. You get it to a depth of about a man's height. Six-plus feet, more or less, would be a reasonable depth for an approach pit. The dimensions of the pit might be 4-foot by 4-foot might be 4-foot by 5-foot, that that order of magnitude. Two people should be able to work inside that space. After you've done the approach pit, of course, you have to put timber sheeting all around it as you go. You know it's not safe to go down five or six feet without some support. You ring it with timber sheeting.

When you have a continuous foundation, you dig an approach pit alongside the foundation. You get it to a depth of about a man's height. Six-plus feet, more or less, would be a reasonable depth for an approach pit. The dimensions of the pit might be 4-foot by 4-foot might be 4-foot by 5-foot, that that order of magnitude. Two people should be able to work inside that space. After you've done the approach pit, of course, you have to put timber sheeting all around it as you go. You know it's not safe to go down five or six feet without some support. You ring it with timber sheeting.

When you've gotten that advanced as far as you want to go, you're ready to now excavate under that continuous foundation. The foundation has to be competent to span even that limited distance, be at 4 or 5 feet. It needs to be able to span that. If you are underpinning a concrete structure, it will certainly span that, but the condition of the soil is another consideration. It's very hard to lay down any hard rules when it comes to underpinning. Every site has to be evaluated and the particular needs of your project and all these subsurface conditions have to be studied to come up with the right method. We will assume the continuous foundation is competent enough to span, so that you can advance the pit underneath the existing foundation.

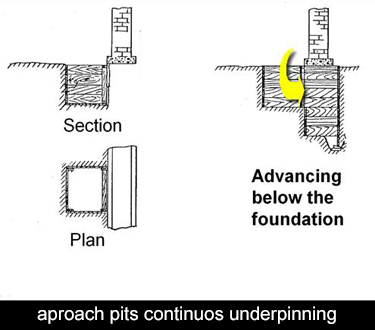

Here you see, the initial pit has been advanced to some predetermined depth. It's ringed with timber sheeting. On the right side, there's an illustration of advancing the excavation below the existing foundation. You can see the same size pit is excavated under the foundation. You put in rings of timber sheeting as you go. Then you occupy that space under the foundation, and you dig down to whatever predetermined depth.

When you have finished, you fill the pit with concrete, not right up to the underside of the foundation. You leave a space, and you allow the concrete to set and let that initial shrinkage take place. Then you fill that void between your new concrete shaft and the existing foundation by dry packing. Dry packing, you make a mixture of mostly cement and some sand and you ram it into place in that space between your new concrete shaft and the existing foundation. You want to fill that space. You want to ensure intimate contact between the existing structure and your new underpinning.

After you've done one pit, you can skip a space, do another pit exactly the same way; fill that with concrete; advance to the third pit, etc. Then you can fall back and do the intermediate pits. Depending on the soil conditions and the absence of obstructions, you actually make excellent progress doing this. Everything is done by hand. The excavation is done by hand. The material is lifted out with a winch and a small pail. It is all hoisted out by hand. The timber planks are cut to size and lowered down the hole. This operation looks the same way that it looked a hundred years ago. It is an excellent practice and produces a continuous concrete wall below the existing wall that you want to re-support. That makes it enormously effective and enormously valuable.

You might remember this slide from cut and cover tunnels. It shows the existing subway tunnel being supported on drilled-in piles. I also pointed out the rock face that is produced under that existing structure. The reason I'm showing you this wall in this case, is that parts of this job have rock, very high rock, which is Illustrated here right up to the existing structure. But parts of this project have earth, which is underlying the existing tunnel. If this was earth and not rock, how do you support it as you try to excavate below the existing tunnel?

You might remember this slide from cut and cover tunnels. It shows the existing subway tunnel being supported on drilled-in piles. I also pointed out the rock face that is produced under that existing structure. The reason I'm showing you this wall in this case, is that parts of this job have rock, very high rock, which is Illustrated here right up to the existing structure. But parts of this project have earth, which is underlying the existing tunnel. If this was earth and not rock, how do you support it as you try to excavate below the existing tunnel?

On either side of the tunnel, you install secant pile walls, but the secant pile wall ends as soon as you reach the existing tunnel. That leaves a long stretch for which there is no traditional means of support of excavation. You cannot put in the secant pile wall. You cannot drive piles for soldier pile and lagging. There's really no way to support this area if it happens to be earth.

Here is a photo of a very similar location. Overhead, you have the underside of the existing subway structure, but under this structure, there was earth. The earth was supported by means of underpinning pits. If you look on the right hand side, you can see this is a perfect illustration of a single underpinning pit. You can see the outline of the boards that were placed to support the earth as you went down. Then this space was filled with concrete. It was dry-packed to meet the underside of the existing tunnel.

Here is a photo of a very similar location. Overhead, you have the underside of the existing subway structure, but under this structure, there was earth. The earth was supported by means of underpinning pits. If you look on the right hand side, you can see this is a perfect illustration of a single underpinning pit. You can see the outline of the boards that were placed to support the earth as you went down. Then this space was filled with concrete. It was dry-packed to meet the underside of the existing tunnel.

Then you have this perfect concrete wall holding back the earth and, of course, also underpinning the tunnel. It's called an underpinning pit and, of course, it's thought of in terms of underpinning the structure above. It certainly can and will do that. It's doing that in this instance, but the primary means of underpinning the existing subway tunnel, were these drilled in piles. They continue to use the drilled in piles. That is the technique that they use throughout the tunnel, where it needs to be supported. But when you reach the end, the edge of your excavation, they had to supplement the drilled in piles with a series of underpinning pits to create a continuous wall of concrete to support the excavation. This is an excellent picture showing the marriage of both of those techniques.

Here's a totally different kind of underpinning. The existing subway tunnel is on the right, but we are in an area which is probably a station. There's this cantilevered section, which is the platform area, and that needs to be held up. What they elected to do here is place these piles external to the station area, which meant they could be done at any time without interfering with either the station or the train traffic. These can be installed in advance.

Here's a totally different kind of underpinning. The existing subway tunnel is on the right, but we are in an area which is probably a station. There's this cantilevered section, which is the platform area, and that needs to be held up. What they elected to do here is place these piles external to the station area, which meant they could be done at any time without interfering with either the station or the train traffic. These can be installed in advance.

You then excavate down to the bottom of the platform and you would create a local excavation, sufficient to attach one of these brackets. The bracket is then shimmed very carefully against the underside of the cantilevered platform and some distance away you get the next bracket. This is a perfectly acceptable method for this. Again, the primary system is taking place under the train tunnel. Those are mini-piles. But this is a kind of a supplement to be used just to accommodate this cantilevered area. Now there's reasonable spacing between these brackets, and you need to be sure that your existing structure is competent to span from one to the next.