I wanted to show you some of the techniques for striking off the concrete. In earlier slides, we saw a very crude approach, seemed to be very little control. This is a more typical procedure, and it exercises some controlled. It still looks rather primitive, but the results seem to be satisfactory. I've lived in several high-rise buildings and the floor looks very flat. You could exercise much more care. You could put down pipes screeds that would precisely control the elevation and the flatness of the concrete. That's obviously not being done here. They seem to get a satisfactory result, and you will at least see a somewhat more organized and controlled procedure in this video.

This is a very cold morning, but they are pouring concrete and the white tarps that you see hanging from the building are used to control the temperature. Within the space, there are typically space heaters, and they keep that area warm. The columns were poured the day before, and they cannot simply be left out to the elements. That floor below is being heated for the benefit of the columns. Also, it's heating the underside of this deck pour. That's the protection they use to allow them to pour concrete during the winter. However, I've never seen the concrete slabs being covered up with any kind of insulated blankets. That would provide additional protection against the cold weather, but they must depend entirely on heating the space below. I love this image. It's one of my favorites. What's going on here? Well, this is the crane and bucket. Apparently, they forgot to pour one column, so they're coming back to pour it now,

This is a very cold morning, but they are pouring concrete and the white tarps that you see hanging from the building are used to control the temperature. Within the space, there are typically space heaters, and they keep that area warm. The columns were poured the day before, and they cannot simply be left out to the elements. That floor below is being heated for the benefit of the columns. Also, it's heating the underside of this deck pour. That's the protection they use to allow them to pour concrete during the winter. However, I've never seen the concrete slabs being covered up with any kind of insulated blankets. That would provide additional protection against the cold weather, but they must depend entirely on heating the space below. I love this image. It's one of my favorites. What's going on here? Well, this is the crane and bucket. Apparently, they forgot to pour one column, so they're coming back to pour it now,

The space behind this column, the deck has already been poured. I'm sure that's when they discovered that they missed one column. To their credit, they could have just taken that floor concrete and put it in the column. As I say "to their credit," they did not do that. The column probably has a different mix and so they brought in some of the column mix. With a crane and bucket, they've gone back to concrete this column that they overlooked.

Just a few feet away, they're placing the concrete. This mason and other masons will determine where the finished top of slab should be. He's holding some kind of a rod, getting a reading from the surveyor. He's creating a good spot. That's the elevation they want. In the background, there is a screed being pulled down by hand. See that activity. They begin by establishing some control points. It's not random. From those control points, they screed off the concrete.

Just a few feet away, they're placing the concrete. This mason and other masons will determine where the finished top of slab should be. He's holding some kind of a rod, getting a reading from the surveyor. He's creating a good spot. That's the elevation they want. In the background, there is a screed being pulled down by hand. See that activity. They begin by establishing some control points. It's not random. From those control points, they screed off the concrete.

Behind that screed a mason is using a bull float to even off the top surface. That's how they control this process. As I say, it looks rather primitive, and it is, but it achieves the correct result.

The concrete was being placed by a pump, I think, up until now, we watched the concrete being placed with the crane and bucket, but at this point it's being pumped. Even though this is a very cold day, I guess an hour or two behind the fresh concrete, the mason is able to trowel it. Now he cannot control the grade. He's just polishing the top surface. That screeding process has to put the concrete down where it belongs. This is just a finishing technique.

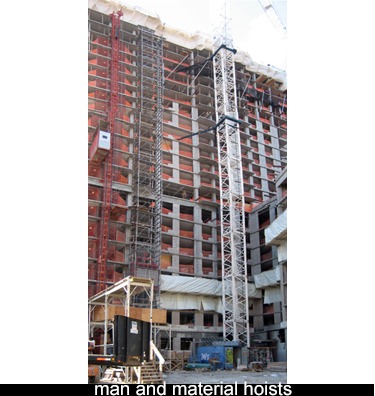

This is a view of the temporary elevators. There's a pair of elevators, which is supported by a central shaft. To the right of the elevators is a material hoist. This arrangement is quite typical, if somewhat different than the arrangement on the steel frame building, which needed more vertical transportation. This is a good overall view. You can see how the tower crane is supported. There's always a loading dock at the foot of the elevators.

This is a view of the temporary elevators. There's a pair of elevators, which is supported by a central shaft. To the right of the elevators is a material hoist. This arrangement is quite typical, if somewhat different than the arrangement on the steel frame building, which needed more vertical transportation. This is a good overall view. You can see how the tower crane is supported. There's always a loading dock at the foot of the elevators.